Localisation and measurement for industrial performance

Reduce time wasted searching for equipment.

Guide operators and increase the traceability of operations.

Analyse the potential for optimising workshop space.

As an Industrial Performance Manager, Operations Director or Operations Manager, you know that continuous improvement is essential to boost productivity.

Continuous improvement can benefit from spatial data

Kaizen and Lean approaches are based on in situ observations, but space-time data is often absent. Measuring the time spent by operators looking for equipment, a place to work or even a production order can help identify areas for performance improvement.

At the same time, standards in a number of sectors require inspection rounds to be traceable, going beyond simple declarations.

While machines connected by Industry 4.0 offer real-time visibility, operators’ activities can also provide objective field data.

Localisation and measurement to optimise operations

The SYSNAV solution makes it possible to measure existing processes and improve operational efficiency through a number of use cases.

Real-time management of operations

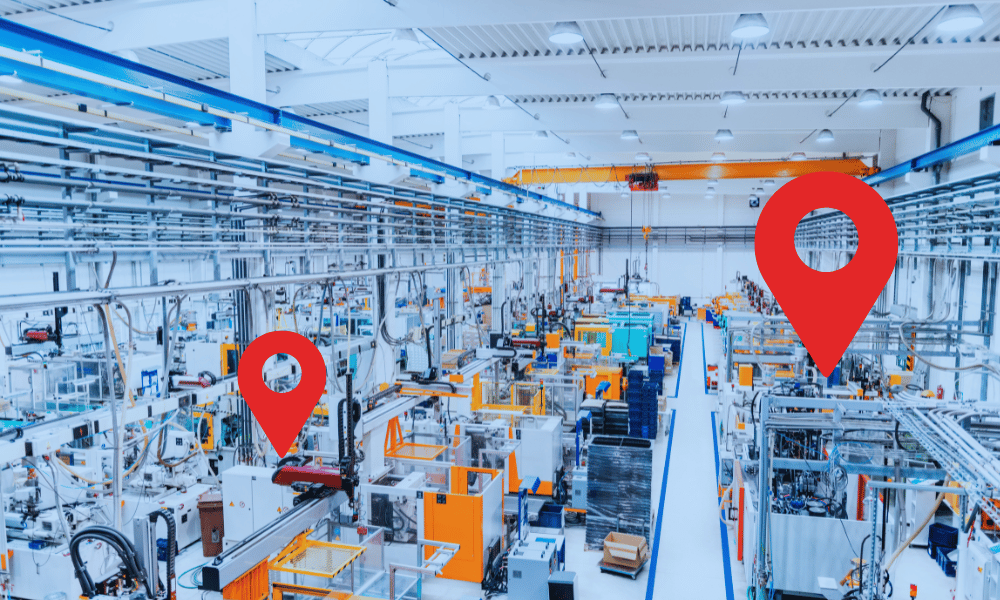

Real-time feedback of the precise positions of people, equipment and vehicles, both indoors and outdoors, means you can

- Quickly locate equipment, saving time and optimising equipment use.

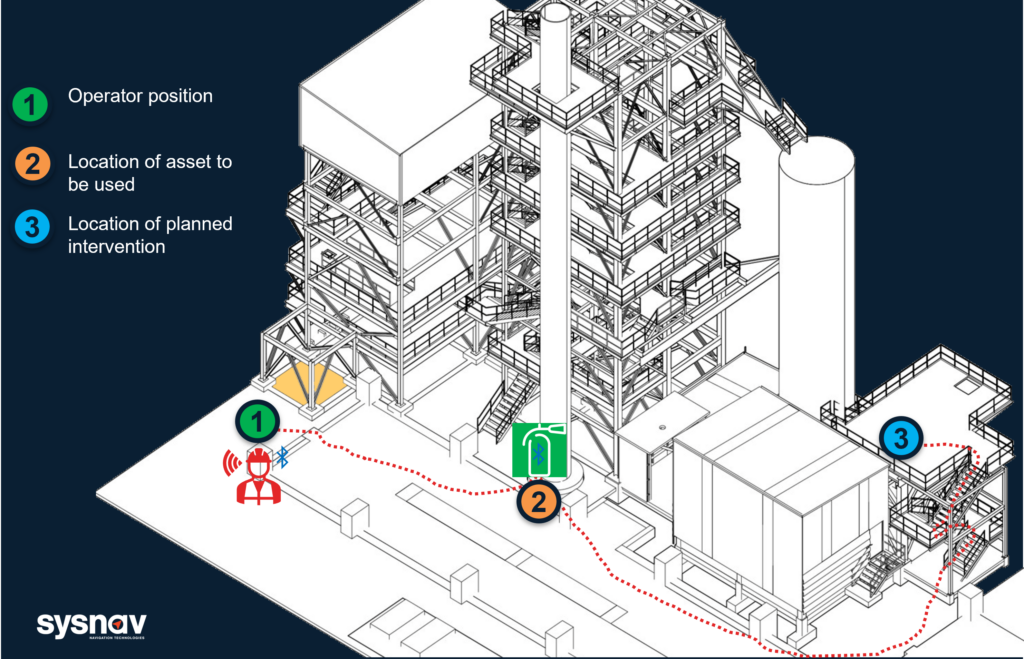

- Guide operators, whether they are unfamiliar with the site (service providers, new recruits) or during site reconfigurations: speeding up interventions and avoiding errors.

- Apply lean management to operations supervision : manage joint activity, prevent work conflicts, anticipate.

Post-process measurement and analysis

Recording the routes taken by people or vehicles on the site generates traces that can be used in several ways:

- Traceability of passage through inspection points: linking presence metadata to declarations to provide evidential value.

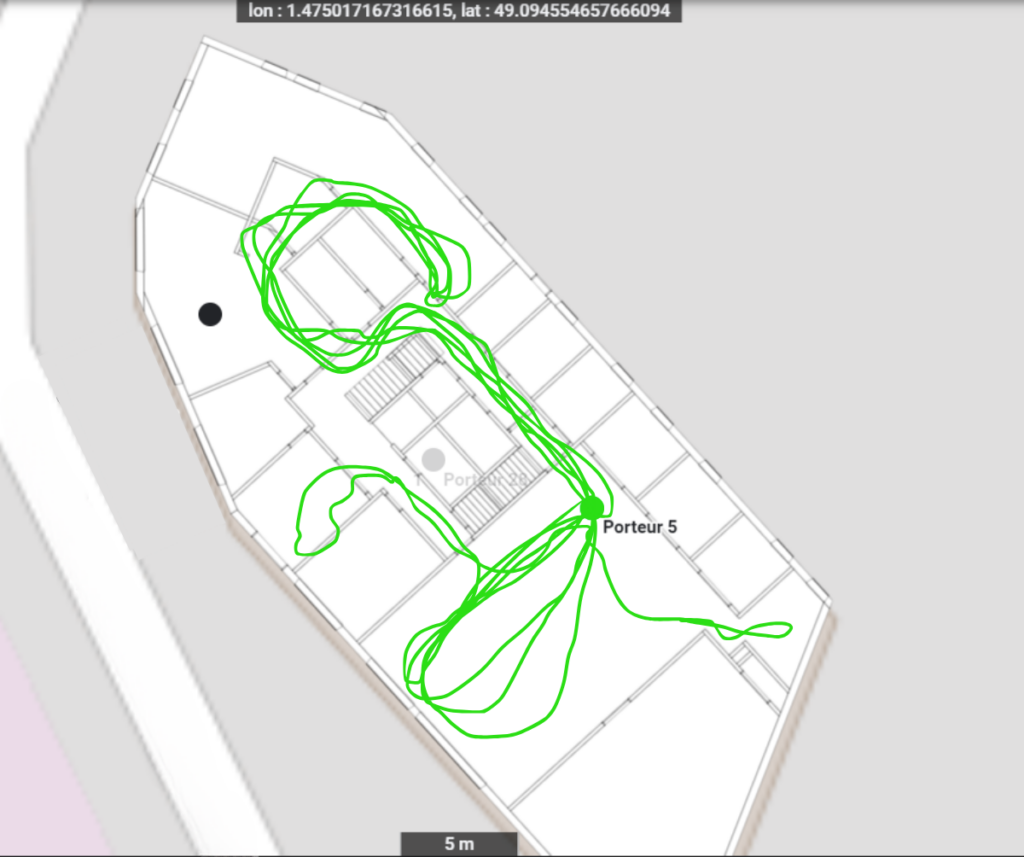

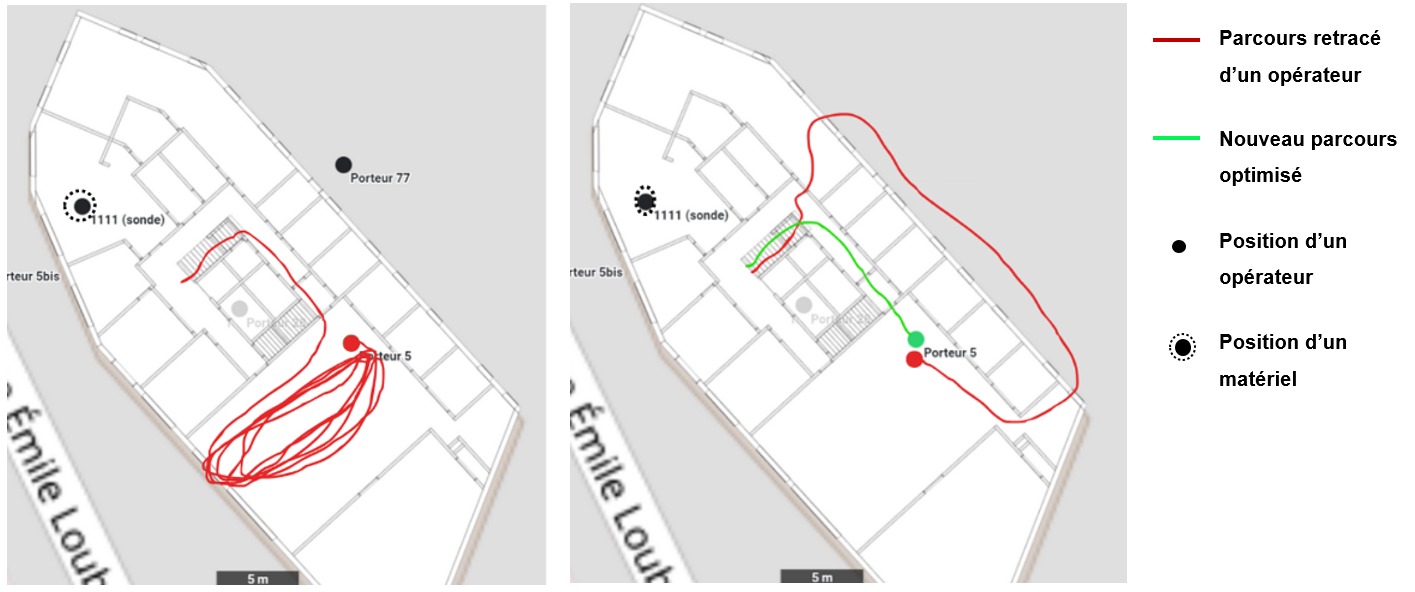

- Spaghetti diagrams for recording movements: acquire objective data over a long period to supplement the observations made.

- By analysing journeys, you can identify areas for optimisation or assess the impact of a workshop reconfiguration.

The SYSNAV solution for Operational Optimization

- Active geolocation tags for operators

- Passive tags for equipment

- No heavy infrastructure to deploy

- Operation via a supervision GIS and a mobile application for guidance

- Interface with CMMS for traceability of interventions

- Data analysis (spaghetti diagrams)

Why SYSNAV ?

- Expertise in locating people and equipment in complex indoor/outdoor environments

- Dedicated support for on-site testing and data analysis

- A 100% European designed hardware & software solution

Brochure

Fill in the form below to download the leaflet:

Our blog posts on the topic:

– High precision positioning for industry 4.0

– Industry 4.0 definitions and applications